INFORMATION

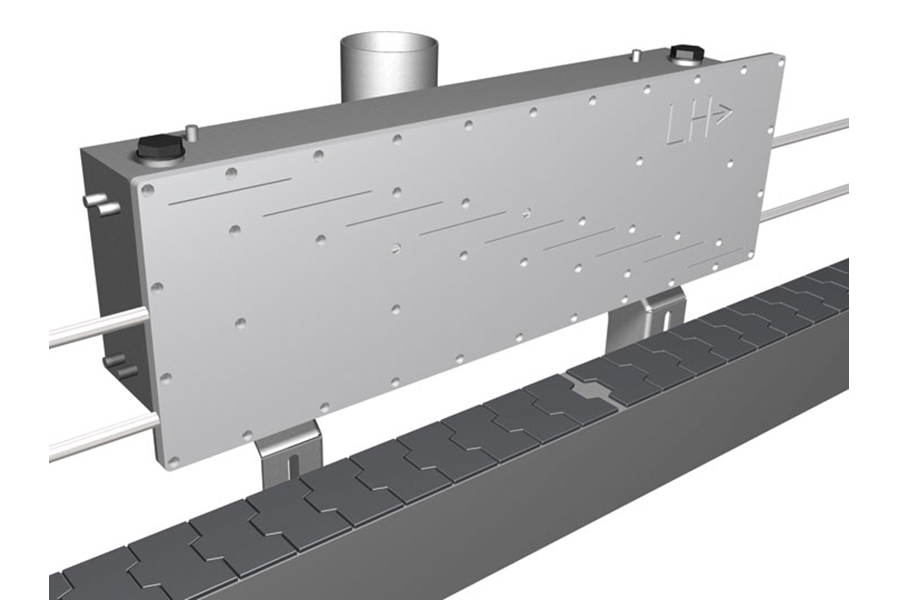

JetPlates – features and other benefits:

- When compared to Air Knives, JetPlates are able to deliver twice the volume of high pressure air over product

- The conveyor guide rail is replaced by the JetPlate. This allows air to be delivered within milimeters of the product

- The JetPlate slot design enables moisture to be directed both downwards and away from the conveyor line, thereby preventing any water recontamination

- The installation of JetPlates simplifies the installation, maintenance and operation processes

- JetPlates require no pitch adjustment to achieve optimum drying performance

- JetPlates can be combined with other ACI Air Delivery Devices

- Different faceplates are available to cater for jars, unsteady bottles as well as an array of traditional bottle & can heights & widths.